You Are Here:Home > News Center

> Industry Dynamics

News navigation

Recommended news

How is the sealing performance of the PP cream jar series

source:www.cssssy.com | Release time:2025-01-21

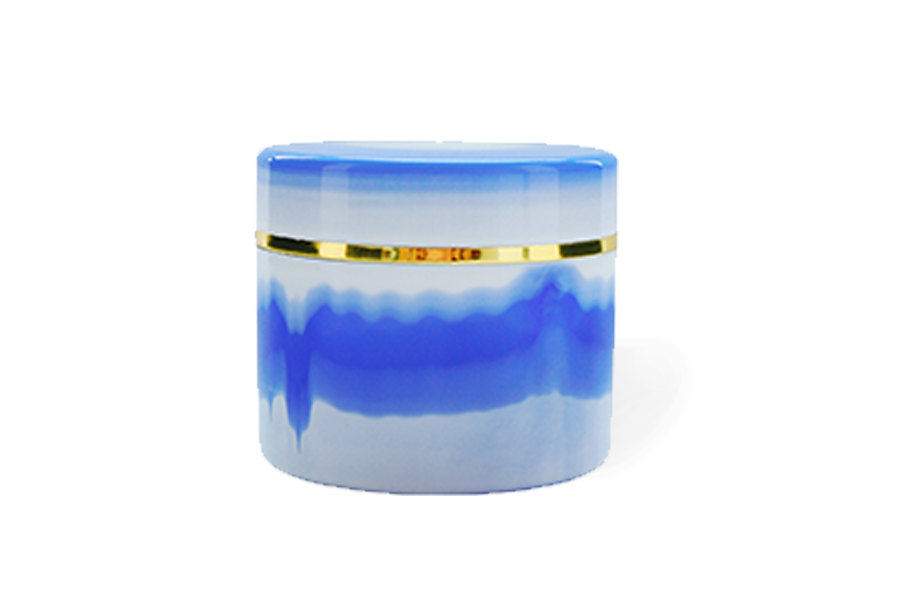

The PP (polypropylene) cream jar series, with its material characteristics and diverse designs, usually has good sealing performance, which is reflected in the following aspects:

1. Material characteristics ensure sealing

Low water absorption: PP material itself has relatively low water absorption, which means that it will not expand or deform due to excessive water absorption in humid environments, thereby damaging the sealing structure of the cream can. For example, when stored in areas with high humidity in the south, PP cream cans can still maintain good sealing to prevent external moisture from entering the cans and affecting the quality of the cream.

Good toughness and chemical resistance: PP has a certain degree of toughness, can withstand a certain degree of compression without breaking, and is stable to most chemical substances. Cream products have complex ingredients, some of which may have certain chemical corrosiveness. PP materials will not undergo chemical reactions with cream ingredients, maintaining the integrity of the tank structure and ensuring stable sealing performance. Like some creams containing plant extracts or special chemical components, storing them in PP cream jars can maintain good sealing for a long time.

2. Structural design enhances sealing performance

Inner plug design: Many PP cream cans are equipped with inner plugs, which are usually made of soft and elastic materials such as PE (polyethylene) or silicone. When the inner plug is inserted into the can mouth, it can tightly fit and form the first line of sealing defense, effectively blocking the entry of air and moisture. For example, some skincare products' PP cream cans have a high fit between the inner plug and the can mouth, resulting in a good sealing effect.

Spiral cap design: PP cream cans often use spiral caps, which tightly connect the cap and the can body through threads. During the tightening process, the sealing gasket between the lid and the can mouth will be compressed, further enhancing the sealing effect. Moreover, the tightening degree of the screw cap can be adjusted to better meet different sealing requirements.

Sealing gasket: A sealing gasket is usually embedded at the contact area between the lid and the tank. The gasket material is mostly rubber or silicone with good elasticity and sealing properties. When the lid is tightened, the gasket undergoes elastic deformation, filling the small gap between the lid and the can mouth, preventing air, moisture, and cream leakage, and greatly improving the sealing performance.

3. Production process ensures sealing

High precision mold manufacturing: In modern production, PP cream cans are injection molded using high-precision molds. The correct mold ensures high dimensional accuracy and tight fit between the tank and lid, reducing sealing issues caused by dimensional deviations. For example, advanced mold manufacturing technology can control the tolerance between the can mouth and lid within a very small range, ensuring sealing performance.

Strict quality inspection: Strict quality inspection will be conducted during the production process, among which sealing performance testing is an important link. By using methods such as negative pressure testing and immersion testing, it is ensured that every cream can meet good sealing standards, and only products that pass the testing will enter the market.

1. Material characteristics ensure sealing

Low water absorption: PP material itself has relatively low water absorption, which means that it will not expand or deform due to excessive water absorption in humid environments, thereby damaging the sealing structure of the cream can. For example, when stored in areas with high humidity in the south, PP cream cans can still maintain good sealing to prevent external moisture from entering the cans and affecting the quality of the cream.

Good toughness and chemical resistance: PP has a certain degree of toughness, can withstand a certain degree of compression without breaking, and is stable to most chemical substances. Cream products have complex ingredients, some of which may have certain chemical corrosiveness. PP materials will not undergo chemical reactions with cream ingredients, maintaining the integrity of the tank structure and ensuring stable sealing performance. Like some creams containing plant extracts or special chemical components, storing them in PP cream jars can maintain good sealing for a long time.

2. Structural design enhances sealing performance

Inner plug design: Many PP cream cans are equipped with inner plugs, which are usually made of soft and elastic materials such as PE (polyethylene) or silicone. When the inner plug is inserted into the can mouth, it can tightly fit and form the first line of sealing defense, effectively blocking the entry of air and moisture. For example, some skincare products' PP cream cans have a high fit between the inner plug and the can mouth, resulting in a good sealing effect.

Spiral cap design: PP cream cans often use spiral caps, which tightly connect the cap and the can body through threads. During the tightening process, the sealing gasket between the lid and the can mouth will be compressed, further enhancing the sealing effect. Moreover, the tightening degree of the screw cap can be adjusted to better meet different sealing requirements.

Sealing gasket: A sealing gasket is usually embedded at the contact area between the lid and the tank. The gasket material is mostly rubber or silicone with good elasticity and sealing properties. When the lid is tightened, the gasket undergoes elastic deformation, filling the small gap between the lid and the can mouth, preventing air, moisture, and cream leakage, and greatly improving the sealing performance.

3. Production process ensures sealing

High precision mold manufacturing: In modern production, PP cream cans are injection molded using high-precision molds. The correct mold ensures high dimensional accuracy and tight fit between the tank and lid, reducing sealing issues caused by dimensional deviations. For example, advanced mold manufacturing technology can control the tolerance between the can mouth and lid within a very small range, ensuring sealing performance.

Strict quality inspection: Strict quality inspection will be conducted during the production process, among which sealing performance testing is an important link. By using methods such as negative pressure testing and immersion testing, it is ensured that every cream can meet good sealing standards, and only products that pass the testing will enter the market.

Previous:

Application of PET plastic bottles in beverage pa…

Next:

What are the characteristics of PE plastic bottles

【Related Products】

- Homepage

- Contact Us

- About Us

- Product Center

- News Center

- MESSAGE

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

苏ICP备18013154号-1

Technical Support:LanGe

Technical Support:LanGe

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone